PORTAL – VR garden with AI feature for plant breeders

The PORTAL project aims to create a prototype of a virtual breeding garden. Using a robot equipped with different types of sensors, plants and parcels on the field are recorded in high resolution and transferred to an advanced virtual representation. Independent of time and space, plant breeders can use it to recognize and examine plant characteristics with AI support. So far, assessments of plant populations have been time-consuming and costly. The DFKI research departments Plan-Based Robot Control from Osnabrück and Cognitive Assistance Systems from Saarbrücken are part of the project.

Partner: NPZ Innovation GmbH (NPZi)

Movi-Q – Quality control in food production

In Movi-Q, a flexible system consisting of AI software and hardware for food classification will be developed and tested. With a transfer-learning approach, not only potatoes and turkey parts will be sorted automatically and objectively for flaws in a manufacturing plant. The feature recognition should be easily transferable to other product lines and production scenarios. For example, the AI system in Movi-Q is being trained to detect rot in potatoes and should later be able to more easily detect rot in vegetables in general. Among other things, the researchers hope the project will provide insights into the use of hyperspectral data and the costs and benefits of the pre-trained solution, which could make AI accessible to a broad user base in the food industry.

Partners: DIL Deutsches Institut für Lebensmitteltechnik e.V. (DIL), sionn.engineering GmbH, Sola Bonum GmbH, Heidemark Mäserkreis GmbH & Co. KG, Wernsing Feinkost GmbH & Co. KG

resKIL – AI without internet connection on the field

A special IT infrastructure is required for the use of agricultural machinery with AI functionalities. Unlike the use of AI in a factory environment with a connected data center, working on the field with tractors or combine harvesters requires a cellular connection that oftentimes can be unreliable or completely missing. Data processing must be able to move, at least partly, to the machine - "on the edge." In resKIL, researchers are developing a technical solution (hardware and software) that should be capable of performing resource-efficient AI calculations on the agricultural machine via an embedded system and variably moving to the cloud when possible.

Partners: CLAAS E-Systems GmbH, Dortmund University of Technology, University of Osnabrück, Zauberzeug GmbH

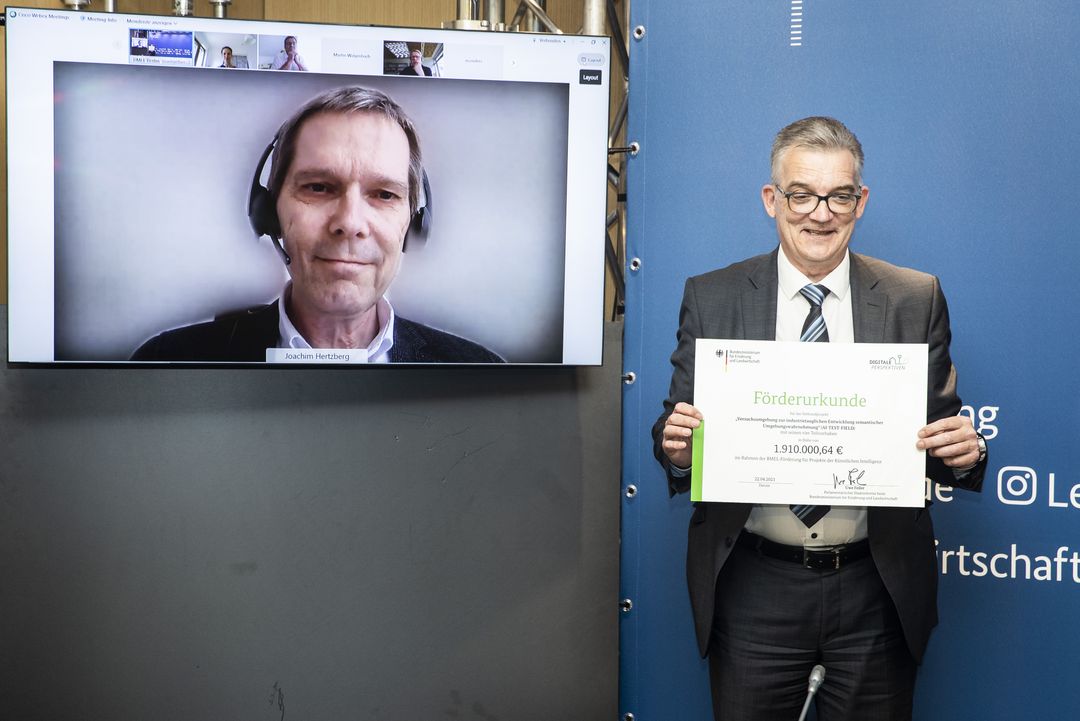

AI-TEST-FIELD – Approval of AI-controlled agricultural machines

Agricultural machines are confronted with extreme environmental influences on the field such as rain, dust, and backlight. For highly automated machines and intelligent assistance systems to be approved for use, safe sensor systems must be developed that reliably detect these difficult environments. For this reason, DFKI is leading the AI-TEST-FIELD project. In a test environment on a farm near Osnabrück, a rail-based sensor vehicle is used to collect data of the environment to evaluate and optimize AI methods such as machine learning and "deep learning".

Partners: Osnabrück University of Applied Sciences, LEMKEN GmbH & Co. KG, Maschinenfabrik Bernard Krone GmbH & Co.