According to the German Environment Agency, more than 1.6 million tons of munitions waste are hidden in northern European waters. These relicts rust, release toxins into the environment, and could potentially detonate in an uncontrolled manner. This not only poses dangers to people and the marine environment but also has economic consequences, as it affects industries such as fishing, shipping, or tourism, and hinders the construction of offshore installations or submarine cable laying. Recovering munitions, including controlled detonation in some cases, is both expensive and extremely risky. Therefore, robots will take over the removal of contaminated sites in the future. This could minimize potential dangers while simultaneously increasing the efficiency of explosive ordnance disposal. However, the systems are currently not capable of handling such a demanding task autonomously.

AI for autonomous underwater robots / German government provides one million euros

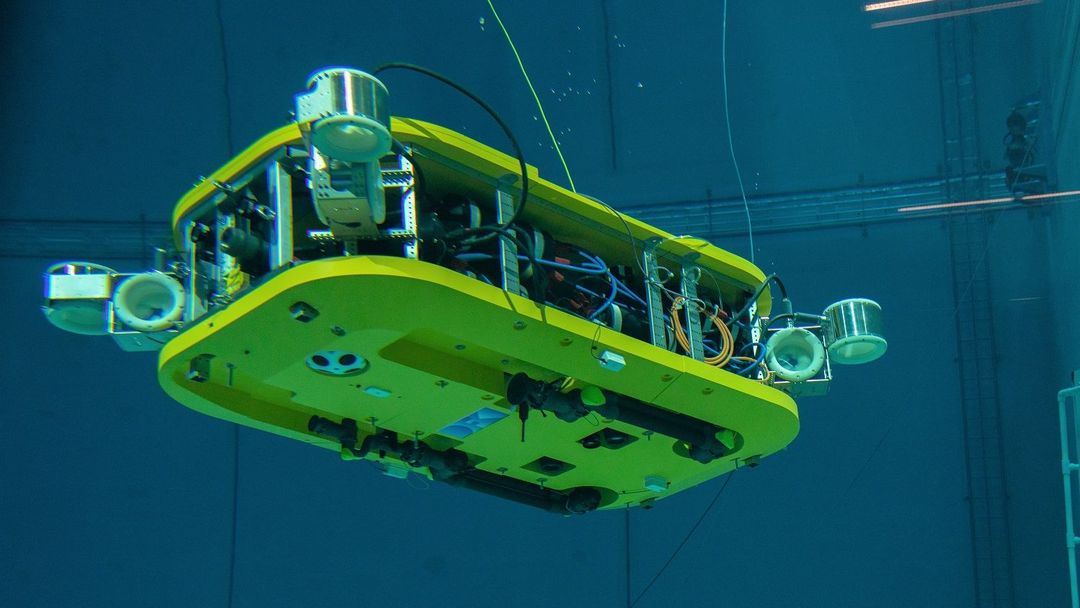

To advance research in this field, the German Federal Ministry of Education and Research (BMBF) is funding the CleanSeas project with around one million euros from January 1, 2023, to December 31, 2025. The project aims to create the technological basis which enables robots to autonomously detect and handle critical infrastructures underwater. Thus, DFKI’s Robotics Innovation Center is developing AI solutions for the following three areas: precise navigation in the close range of critical objects, 3D reconstruction of objects using various sensors, and whole-body control for (partially) autonomous object manipulation. The autonomous underwater vehicle (AUV) Cuttlefish developed at DFKI serves as the robotic test platform. The innovative robot has two deep-sea capable gripping systems for flexible handling of objects underwater. Thanks to its special design and AI-based control, it can change its center of gravity and buoyancy during a dive and assume any orientation.

Comprehensive environment perception thanks to sensor fusion and generative AI

In the case of recovering munitions from oceans, the AUV must be able to approach its target object without colliding with it. For this purpose, the vehicle is equipped with a variety of sensors such as sonars, cameras, laser scanners, and magnetometers. However, due to the highly variable environmental conditions underwater, the robot can only partially sense its surroundings at a low resolution. This significantly impedes navigation as well as object detection. For this reason, the scientists combine acoustic and optical sensor data using probability-based sensor fusion. Thus, the quality of the high-resolution camera data especially depends on the prevailing light and visibility conditions. Acoustic sensors, however, are independent of visibility conditions, but only provide data with significantly lower resolution. In addition to that, their functionality is severely limited at close range. To close the gaps in object detection, the researchers are also relying on the use of generative AI algorithms. This involves training a neural network so that it can generate camera-like images based on low-resolution sonar data. That way, a comprehensive reconstruction of the target object in 3D is possible.

Whole-body control combined with learned behavior for precise manipulation

Controlling the robot is particularly difficult, as its structure changes whenever its gripping systems are moved out. Thus, classical methods are not suitable for robotic manipulation under water. To enable precise arm movements, the entire vehicle, including the arms, must be included in the control. Therefore, the scientists resort to modern approaches of whole-body control, which they combine with learned behavior. A deep neural network-based algorithm learns how the vehicle behaves under different conditions. Thanks to the learned hydrodynamic model, the AUV can precisely readjust its pose automatically at runtime. To avoid arm collisions, the researchers are also developing software that coordinates arm movements in real time. Tactile force sensors on the robotic grippers allow sensitive and, in case of doubt, compliant handling of ammunition residues.

Evaluation of different attachment concepts / laboratory tests with old ammunition

The aim of the manipulation is to attach lifting gear to the casings of old ordnance in order to lift and transport it. Therefore, the scientists are investigating various concepts, which they will then translate into corresponding robotic behavior, such as attaching lifting gear to existing eyelets, looping around and tightening the ammunition with straps, or trapping it with nets. The technologies developed will initially be tested under controllable laboratory conditions. For this purpose, the researchers have access to the DFKI's Maritime Exploration Hall in Bremen, which is unique in Europe. The plan is to sink old ammunition in the 8 m deep saltwater basin, which contains 3.4 million liters of saltwater, and place it in sandboxes installed inside.

Key technologies with high ecological and economic relevance

Prof. Dr. Frank Kirchner, Head of the DFKI Robotics Innovation Center: "Innovative robotics systems of the latest generation, which are able to perform highly complex data analyses and manipulation processes on dangerous or sensitive objects and infrastructures in environments hostile to humans over long periods of time with consistent precision using methods of artificial intelligence and machine learning, are the key technology to tackle this mammoth task and at the same time only the first step. Germany is thus setting standards for work in ecologically sensitive areas and gaining a technological competitive edge over its international competitors."

The robotic solutions envisioned in the CleanSeas project could not only be an important tool for solving the munitions problem in the world's oceans but also promote the expansion of renewable energies and the sustainable use of maritime resources. For instance, these technologies could be used to advance the development of robots that autonomously perform maintenance and inspection work on facilities of offshore wind farms, terminals to produce green hydrogen or aquacultures.