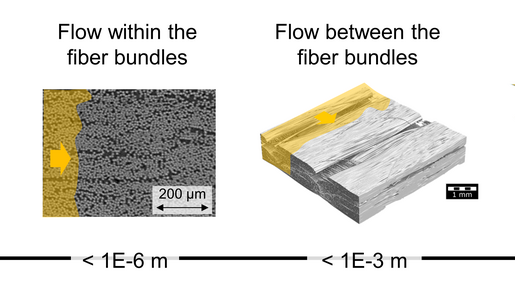

Nowadays, process simulations, often based on the finite element method, are used to support process design. Here, physical properties are attributed to finite elements that represent the processing behavior of fibers, polymers or a combination of both. However, the inherent complexity of fiber structures leads to major challenges in representing these properties, since physical effects occur at very different temporal and spatial scales. This is particularly evident in Liquid Composite Molding (LCM) processes where a dry fiber structure is infiltrated with a liquid resin system. During impregnation, flows occur within the fiber bundles (within flow channel diameters of a few μm), which are influenced by capillary pressures, while, at the same time, flows between the fiber bundles (flow channels several mm in size) are strongly dependent on the differential pressure applied in the process. These effects have to be considered and understood in the process simulation which requires complex simulation models at each of the different scale levels (Figure 1).

The project "ML4ProcessSimulation"

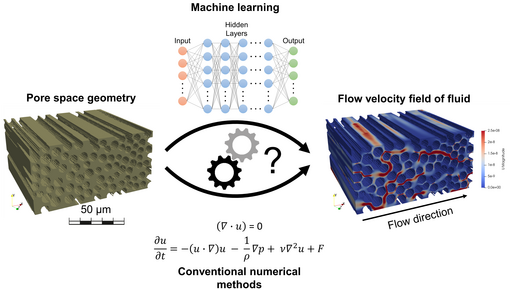

The project "ML4ProcessSimulation - Machine Learning for Simulation Intelligence in Composite Process Design" addresses the key challenge of developing effective multiscale simulation methods that take all relevant physical effects from the fiber to the component level into account but still remaining manageable in terms of computational effort. For this purpose, innovative machine learning methods are combined synergistically with conventional simulation methods (Figure 2). In addition to Data Driven Methods and Physics Informed Neural Networks (PINNs), machine learning based Model Order Reduction (MOR) techniques are being investigated in order to realize computationally efficient simulations. Furthermore, the project explores how existing process knowledge regarding the physical relationships can be incorporated into the simulation workflow in order to improve the quality of the predictions.

The project is funded by Leibniz Association after a success in the highly competitive Leibniz Competition. The project consortium combines core competencies from Science and Innovation Alliance Kaiserslautern (SIAK) and Leibniz Association: The project is led by Leibniz-Institut für Verbundwerkstoffe (IVW), in collaboration with Fraunhofer-Institut für Techno- und Wirtschaftsmathematik (ITWM) and Deutsches Forschungszentrum für Künstliche Intelligenz (DFKI). In addition, two more Leibniz institutes, Weierstraß-Institut für Angewandte Analysis und Stochastik (WIAS) and Leibniz-Institut für Polymerforschung (IPF) complete the extraordinary research team together with two internationally renowned professors J. Nathan Kutz (University of Washington) and Suresh Advani (University of Delaware) who participate as mentors. Launched in spring 2022, the first major consortium meeting took place in Kaiserslautern in fall (Fig. 3). In addition to a productive exchange, the program included interesting tours through the laboratories and facilities of IVW, ITWM and DFKI.

The project „ML4ProcessSimulation - Machine Learning for Simulation Intelligence in Composite Process Design” is funded by Leibniz Association within Leibniz Collaborative Excellence funding programme (funding reference: K377/2021).