AI-based monitoring of 3D printing

| Environment & Energy | Marine Perception | Osnabrück / Oldenburg

Software solutions for 3D printing from Oldenburg

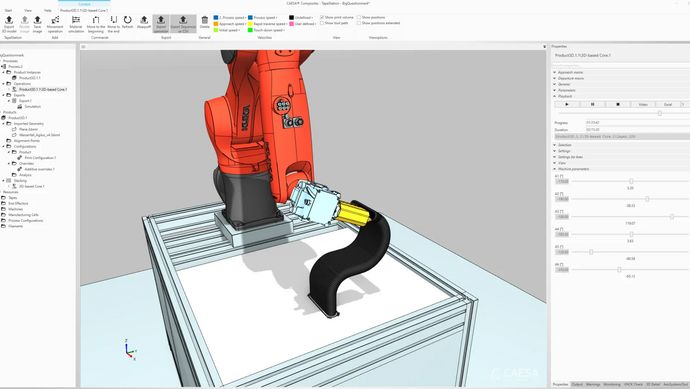

SWMS Systemtechnik Ingenieurgesellschaft mbH, founded in 1996, is a technology company for digital industry solutions based in Oldenburg, Lower Saxony. With around 40 employees, the company offers software solutions in the complex field of automated composite manufacturing that support customers from the design of composite components to their production. All activities are bundled in the CAESA software environment in corresponding modules and are available as plant- and manufacturer-independent programming and design software. SWMS’ customers include companies in the aerospace, automotive, shipbuilding and wind power industries.

Challenge: Reducing printing errors through AI-supported monitoring

One of the company's major challenges is to continuously monitor the 3D printing process to terminate the printing process when defects occur or, ideally, to take countermeasures, such as active cooling, to maintain the print and keep the component intact. Since additive manufacturing must also be economically viable for smaller batch sizes (down to a batch size of one), it is essential that components can be reliably manufactured without extensive running-in measures.

When manufacturing composite components, flat parts can be produced using traditional methods, such as pressure moulding. By 3D printing supporting structures in this mould, the rigidity of these components can be significantly increased. However, if the 3D printing fails, the entire component may have to be scrapped.

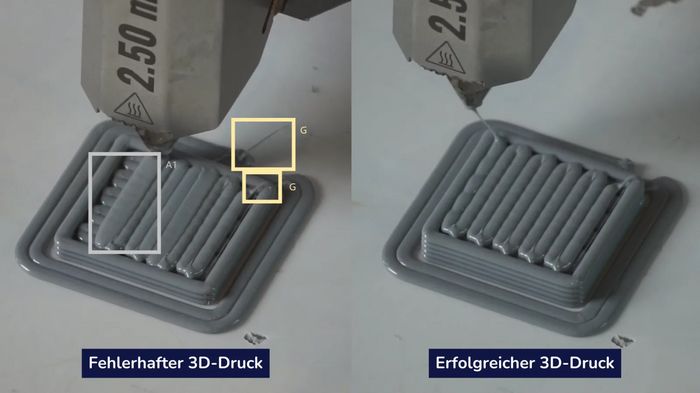

Currently, quality control usually only takes place after the printing process is complete. An ideal solution would be to detect any deviations during the printing process and to initiate countermeasures. Even just detecting an error and aborting the printing process without taking countermeasures would lead to material savings and an increase in resource efficiency.

© SWMS Systemtechnik Ingenieurgesellschaft mbH

© SWMS Systemtechnik Ingenieurgesellschaft mbH © SWMS Systemtechnik Ingenieurgesellschaft mbH

© SWMS Systemtechnik Ingenieurgesellschaft mbHAI-supported object recognition and image segmentation as a solution

This is precisely where artificial intelligence can help. AI-supported object recognition or image segmentation can identify printing errors and initiate countermeasures. The AI used here learns image-based object recognition and segmentation through deep learning approaches.

In order to use AI’s full potential, the AI model must first be trained accordingly. To do this, data from the sensors, such as the nozzle and thermal camera, must first be recorded and labelled manually. After that, training with labelled data is necessary before the recognition performance can be determined in use. Once the training is complete, the AI model monitors the live images from the camera, which over time can reduce completely eliminate manufacturing defects.

Added value through AI for companies and customers

The defect detection component developed in the pilot project for 3D printing is intended to become part of a control software for non-planar 3D printing, thus creating an additional service component for the customer. The component itself is used for continuous quality control of the production process. This results in several advantages, both for customers and the company itself.

Firstly, the aim is to integrate the AI component into the existing control software for additive manufacturing so that the component becomes part of a complete solution. secondly, in the longer term it should lead to a general improvement in the quality of additive 3D printing, since the continuous collection of sensor data over a longer period of time will create a broader basis for not only detecting errors, but also for identifying and eliminating their causes.

Resource savings through integration of AI-supported monitoring in customer systems

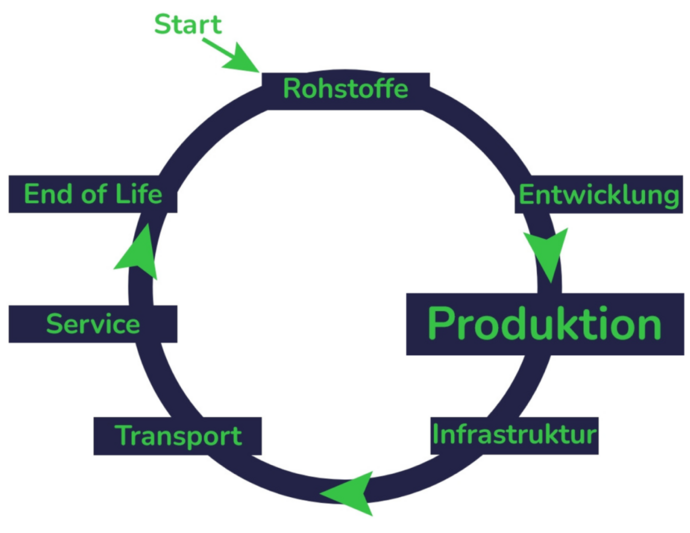

The monitoring particularly addresses the areas of service and production in the value chain. SWMS Systemtechnik Ingenieurgesellschaft mbH is a technology company for digital industry solutions and not a direct provider of 3D printing services, so the AI process initially has little impact on resource efficiency in its own company (in the context of testing and developing the pilot). However, the integration of a defect detection component into the control software for additive manufacturing has a multiplier effect, as the software can be used by many different companies.

As the printed objects are continuously monitored for defects during the printing process instead of being controlled after the printing process is complete, the AI solution will have a significant impact on the consumption of printing material, known as filament.

It is estimated that this can save about a third of the material used for desktop 3D printing. In addition, resources are saved for operating and controlling the robot arm, heating the filament and, if necessary, actively cooling the printing material.

The costs for the specific application of the AI solution are relatively low, since these only require the trained AI model to evaluate the visual data from the cameras, which can be carried out with standard hardware. Higher costs arise when training the AI models, since the training cycles usually require more powerful hardware or access to computing clusters. In addition, costs arise from the manual labelling of the data and the use of sensors, the computer for storing the data, the license fees for the system software and the construction material for the setup. How quickly the investments pay off depends on several parameters, such as the print volume, the amount of filament used as well as the tolerance range for deviations in printing.

Value creation

Phase: production & service

Aim of AI: error detection and avoidance in 3D printing of components

Resource efficiency

GHG reduction potential of 2.53 tonnes CO2e

Savings in printing material (filament) and energy

The Green-AI Hub Mittelstand is an AI initiative of the Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Nuclear Safety and Consumer Protection (BMUV) and is coordinated by Zukunft – Umwelt – Gesellschaft (ZUG) gGmbH. The initiative is paving the way for the use of AI for resource efficiency and material savings. It is specifically aimed at SMEs: practical, solution-oriented and on-site. For sustainable economic growth, securing the future of medium-sized companies and the environment in which we live.

Contact:

Dr. Frederic Theodor Stahl

- Frederic_Theodor.Stahl@dfki.de

- Phone: +49 441 99833 4713

Prof. Dr. Christoph Tholen

- Christoph.Tholen@dfki.de

- Phone: +49 441 99833 4721