- SmartFactoryKL introduces new, comprehensive cloud platform at Hannover Messe

- Network of clouds of different companies linked in the SmartFactoryKL cloud

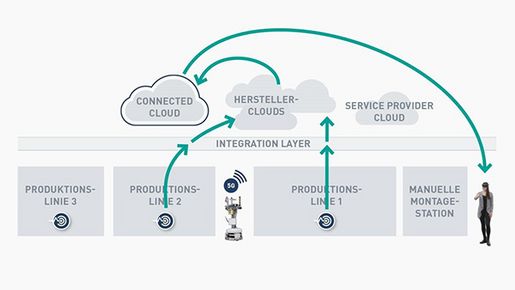

Manufacturing companies use data-driven applications to make reliable predictions about the status of the production plant. Various cloud solutions necessary for data analysis and interpretation are available on the market. Each of these solutions provides the expert knowledge required for reliable data interpretation for the specific application. These individual clouds initially present manufacturer-specific solutions. The various production data can only be merged to provide an overall picture of the plant in a manufacturer-independent manner when networked through a higher level cloud platform.

Use Case SmartFactoryKL Cloud

SmartFactoryKL demonstrates just such a cloud platform – one that aggregates the entire expert knowledge of all cloud solutions – in collaboration with its partners at the production plant. At the SmartFactoryKL facility, various cloud solutions are connected to the assembly modules by the corresponding edge devices. For example, for predictive maintenance the quality assurance module uses a different cloud than the assembly module.

The SmartFactoryKL cloud, as the higher level cloud platform, merges the data from the separate manufacturer clouds and checks it before making the targeted distribution. In this way, the SmartFactoryKL cloud draws conclusions from faulty or deviant data and communicates the appropriate maintenance instruction via smart phone or a smart device

like data glasses to the worker. The user-specific services of the future will still be provided only by experts, i.e., the suppliers of individual cloud solutions. This means that a company is required to access multiple clouds containing different data. For practical purposes, this implies a manufacturing cloud platform that can be networked with the various clouds in use.

Additional Use Case: Service-provider cloud via 5G technology

The Service Provider Cloud is directly linked via 5G technology to the flexible transport system and carries out the actual quality control using the optical recognition data for the workpiece (see press release “5G” dated: March 6, 2018).

“We see an emerging trend that clouds, like machines, can be viewed as services that can be modularly combined. Consider the pay-per-use payment system, where the user pays only for the services that have been called up from multiple providers. Another advantage in exploiting cloud platforms is the relative ease of operation. For example, even automation developers who are not IT experts use this concept,” said Prof. Dr. Detlef Zühlke, CEO of SmartFactoryKL.

The partners involved in the Industrie 4.0 demonstrator at SmartFactoryKL are:

Belden/Hirschmann, Bosch Rexroth, B&R Automation, EPLAN Software & Service, Festo, HARTING, Huawei, IBM, KIST Europe, LAPP KABEL, METTLER TOLEDO, MiniTec, PHOENIX CONTACT, Pilz, proALPHA, SAP, Siemens, TÜV SÜD, and Weidmüller.

About the Technologie-Initiative SmartFactory KL e.V.

The SmartFactoryKL technology initiative was established as a non-profit organization in 2005, bringing together for the first time industrial and research partners in an Industrie 4.0 network to implement joint projects for the factories of the future. SmartFactoryKL is a unique, manufacturer-independent demonstrator and research vehicle located at the German Research Center for Artificial Intelligence (DFKI) in Kaiserslautern. Promising innovative Information and Communication Technologies (ICT) are evaluated and further developed in a realistic industrial production environment on site. Products and solutions as well as universal standards in the areas of Industrie 4.0 have already been developed at the technology initiative with the active participation of its members. Together with other regional competence suppliers, SmartFactoryKL was recognized by the German Federal Ministry for Economic Affairs and Energy (BMWi) and designated as SME 4.0 Competence Centrum Kaiserslautern:

www.smartfactory.de

Press contact:

Dr. Haike Frank

Head of Public Relations Department

Technologie-Initiative SmartFactory KL e.V.

Trippstadter Straße 122

D-67663 Kaiserslautern

Phone: 0631/20575-3406

e-mail: frank@smartfactory.de

Christian Heyer

DFKI Communications Department Kaiserslautern

German Research Center for Artificial Intelligence (DFKI)

Trippstadter Straße 122

D-67663 Kaiserslautern

e-mail: communications-kl@dfki.de