Automated waste sorting is a key component of a sustainable circular economy. While smaller waste fractions, such as packaging and paper, can be mechanically separated in conveyor-guided sorting systems, large pieces of waste, such as bulky and construction waste, still pose a challenge. Currently, these materials must be laboriously shredded before they can be sorted in conventional plants. This process is inefficient, costly, and energy-intensive.

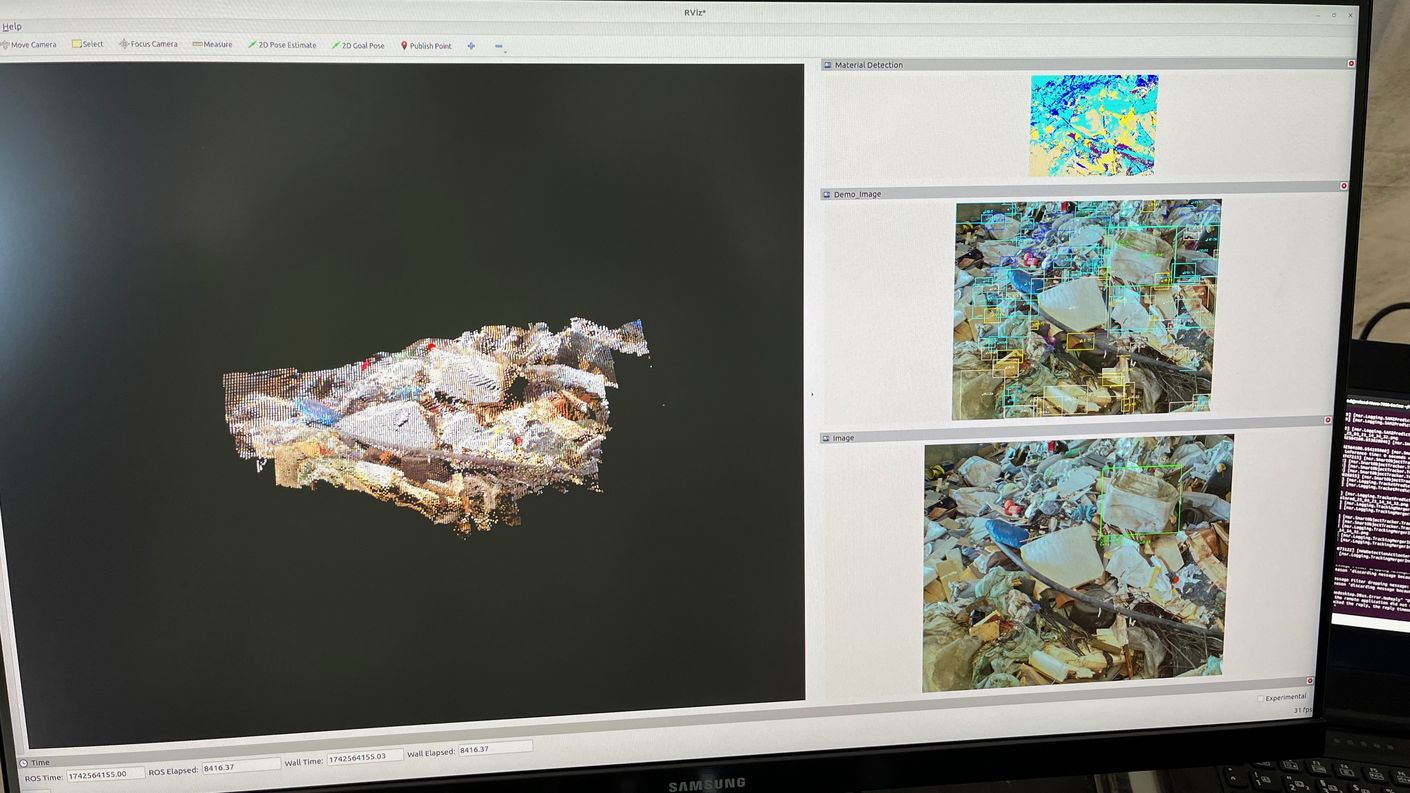

These challenges provided the impetus for the SmartRecycling-Up project, which was funded by the Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection (BMUV) as part of the "AI Lighthouses for the Environment, Climate, Nature and Resources" funding line. The project’s goal was to develop an AI-based solution for sorting large waste objects without the need for mechanical shredding. A particular focus was placed on the automated recovery of valuable materials such as wood, plastic, and metal – components that are often difficult to separate from mixed waste streams. The aim: to significantly increase recycling efficiency, conserve resources, and raise overall recycling rates.