Low-threshold access to Quantum AI services in production

© Oliver Dietze

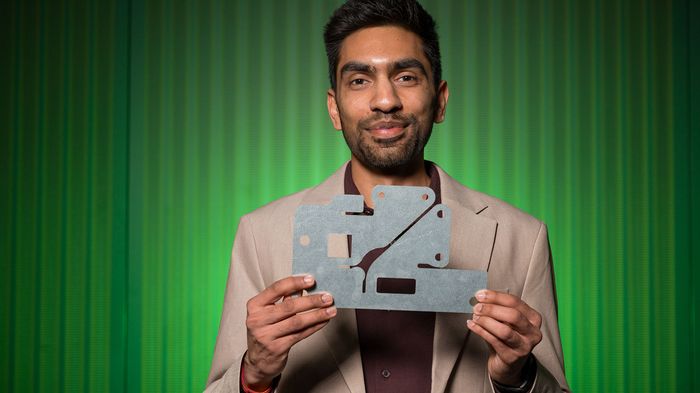

© Oliver DietzeBefore processes such as lasering, cutting, and milling are performed, simulations of the subsequent processes are used to avoid errors. However, existing numerical and data-driven simulations require extensive computing resources and therefore take a disproportionately long time or, in some cases, cannot even be implemented due to their complexity. This is a difficult situation for an industry that is even more dependent than others on optimization and the highest quality in order to remain competitive.

The QUASIM project is investigating how existing simulation methods can be supported or replaced by quantum computing (QC). By using quantum computing and quantum machine learning, simulations are to be accelerated and realized with higher resolution in order to optimize machining processes and reduce scrap. In the quantum AI services that the researchers are investigating, the quantum technological relationships should be presented in such an abstract way that the user can rely purely on the use of QC-based software.

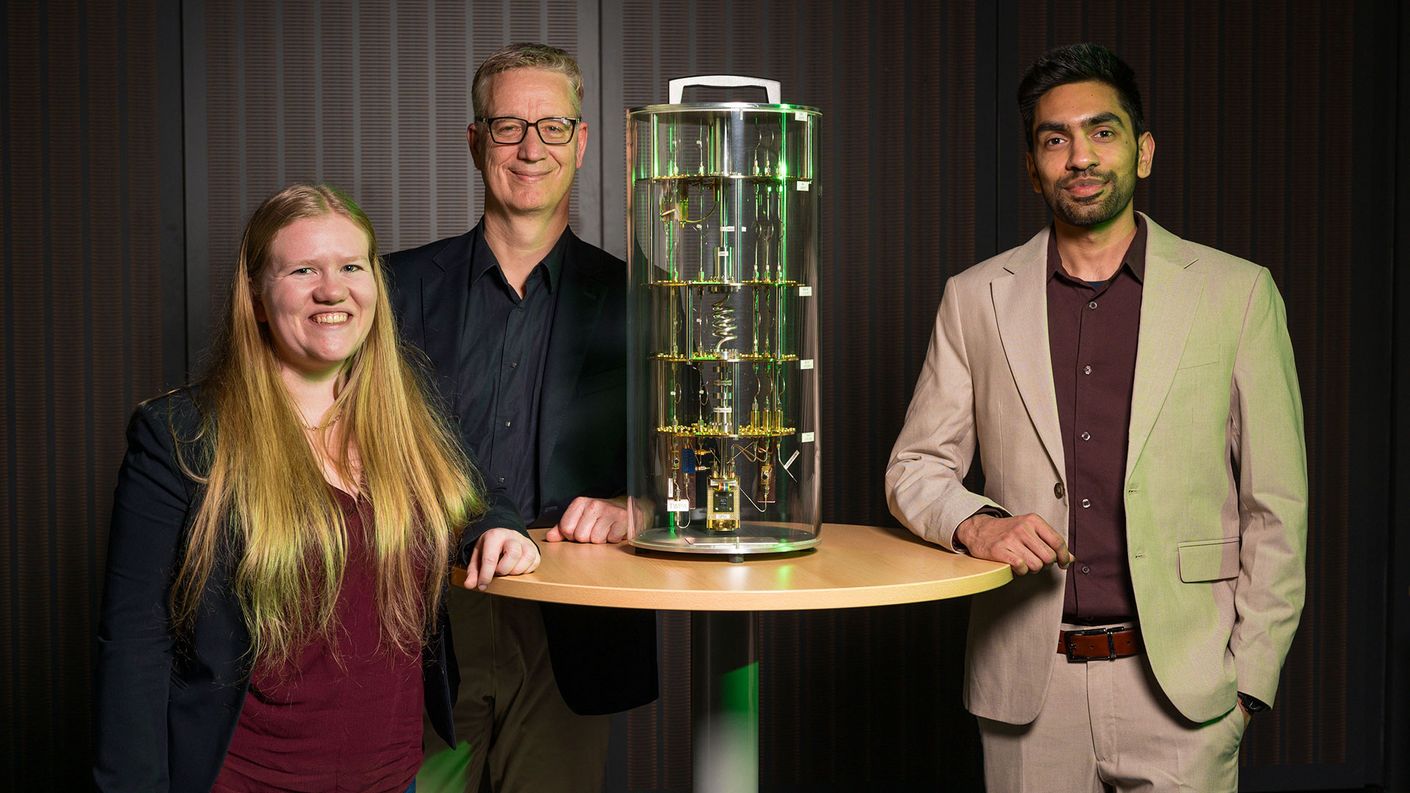

A technical prototype with a user interface for Quantum AI Services for simulations in laser cutting will be on display at the Hannover Messe (Hall 2, Stand B 10). Visitors can interact directly with the system on site and carry out QML-based simulations.

QUASIM is being funded by the Federal Ministry of Economics and Climate Protection (BMWK) from 1.1.22 to 31.12.24 with a sum of approx. 5.2 million euros. The partners are: Forschungszentrum Jülich, Fraunhofer Institute for Production Technology IPT, ModuleWorks GmbH, TRUMPF Werkzeugmaschinen GmbH + Co. KG.

Back to: DFKI at Hannover Messe 2024

5 Minute Pitches about QUASIM

- 24.04., between 13:30 - 14:00 (Hall 2, BMWK Stand)

- 25.04., between 16:35 und 17:05 (Hall 2, BMWK Stand)

- 25.04. between 12:00 und 12:30 (Hall 12, DLR QCI Stand)

Press Contact

For interviews and discussions with our AI experts

Jennifer Oberhofer

Phone: +49 541 386050 7088

Jennifer.Oberhofer@dfki.de

Heike Leonhard

Phone: +49 681 85775 5390

Heike.Leonhard@dfki.de