Print4PAUL

Flexible production and energy monitoring

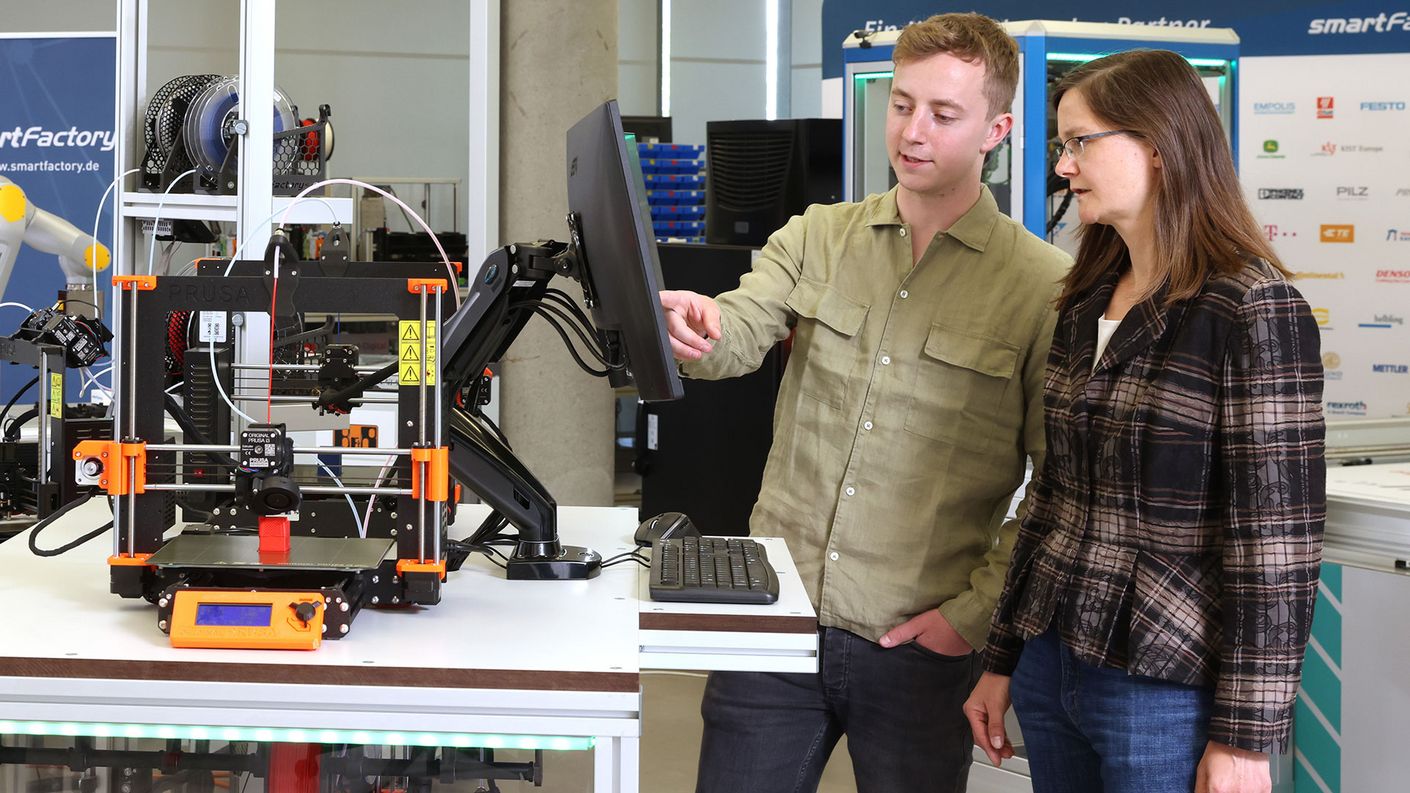

Print4PAUL demonstrates alternative, flexible production possibilities using 3D printing, which become relevant, for example, if parts of a production plant fail. The energy consumption of the orders is monitored and can be predicted for future production orders, which directly fulfills reporting requirements. Print4PAUL thus shows how energy monitoring can accompany and specifically support production.

Shared Economy

Print4PAUL is part of the demonstrator landscape of the technology initiative SmartFactory-KL, which is based at DFKI in Kaiserslautern. In this concept, several production islands at different locations work together via a data room in Kaiserslautern as a skill-based production network (shared production). They take on different roles in the production process and work together to build an individually configurable model truck as an example product.

The Mittelstadt Digitalzentrum Kaiserslautern

The Mittelstand-Digital Center Kaiserslautern offers professional support to small and medium-sized companies in Rhineland-Palatinate and beyond in identifying and implementing the potential of digitalization. As part of the Mittelstand-Digital network funded by the Federal Ministry for Economic Affairs and Climate Protection (BMWK), the services include free training, workshops, and information events. Thanks to its close ties with the technology initiative SmartFactory-KL and the German Research Center for Artificial Intelligence (DFKI), the MDZ has a broad, up-to-date knowledge base and many years of experience in the realization of Industry 4.0.

Back to: DFKI at Hannover Messe 2025

Contact

Mittelstand-Digital Zentrum Kaiserslautern

Larissa Theis

Research Departent Innovative Factory Systems

Phone: +49 631 343773 35

larissa.theis@mdz-kl.de