Green-AI Hub Mittelstand

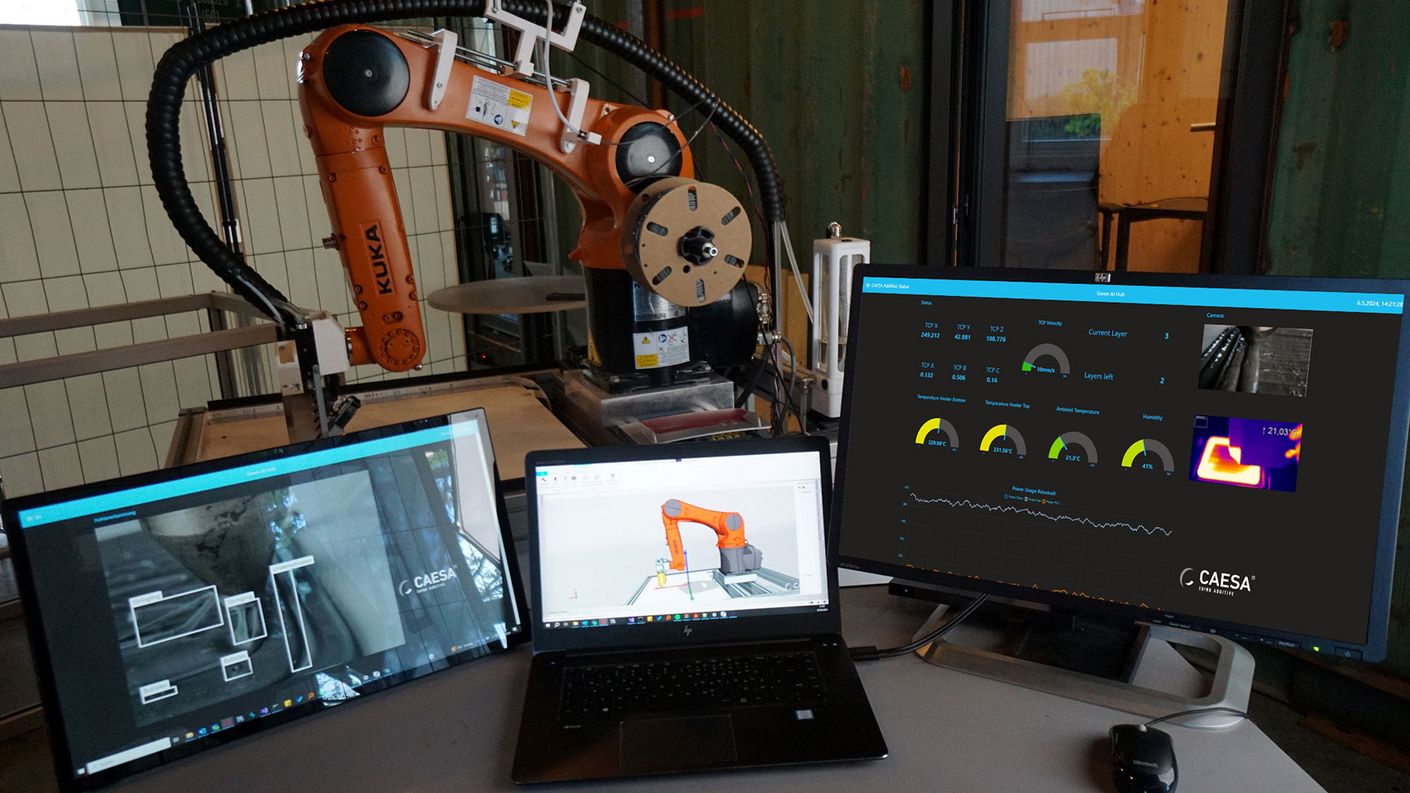

AI-based monitoring of 3D printing

© SWMS GmbH, Lars Windels

© SWMS GmbH, Lars WindelsComposite components used in industry – particularly in the aerospace, automotive, marine, and wind energy sectors – are traditionally manufactured using print molds. This method enables the production of flat parts, whose stiffness can be further optimized by integrating 3D-printed support structures. But what happens if errors occur during 3D printing? The entire part may become unusable.

Artificial Intelligence (AI) can provide a solution: With AI-powered object recognition and image segmentation, printing errors can be detected at an early stage, allowing immediate corrective action. This enhances production quality and reduces material waste. The Green-AI Hub Mittelstand, an AI initiative of the German Federal Ministry for the Environment, Nature Conservation, Nuclear Safety, and Consumer Protection (BMUV), is developing and testing this technology in collaboration with SWMS Systemtechnik Ingenieurgesellschaft mbH. The Oldenburg-based technology company specializes in software solutions for the automated production of composite materials.

The Green-AI Hub Mittelstand supports companies across Germany in implementing AI projects to reduce resource and material consumption. It focuses particularly on small and medium-sized enterprises (SMEs), offering practical, solution-oriented, and on-site support. The initiative is coordinated by Zukunft - Umwelt - Gesellschaft (ZUG) gGmbH on behalf of the BMUV, with DFKI, the Wuppertal Institute and the VDI Technology Center responsible for implementation.

Back to: DFKI at Hannover Messe 2025

Contact

Dr. Christoph Tholen

Research Department Marine Perception

Christoph.Tholen@dfki.de

Phone: +49 441 99833 4721